During the welding process, the casing pipe and the sleeve are heated and liquefied in a specific area. In this melted area, the materials fuse together in such a way that they cannot be broken apart again. The result is a durable, sealed weld. The INDUCON fusion coupler is the reliable solution that boasts exceptional strength and reliability. It is therefore also suitable for difficult ground conditions, as well as groundwater and pressing water.

For more information and documentation, please visit the specific INDUCON website.

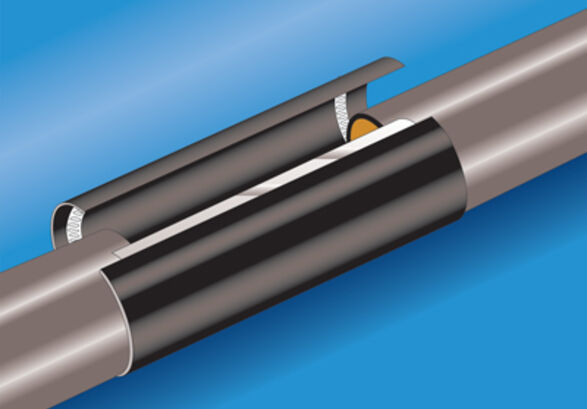

Fully prefabricated HDPE plate that can be installed immediately before welding. The connection boasts consistent quality, even under difficult or restricted installation conditions. HDPE plate with heating conductor and temperature sensor on the inside.