The test certificates state that connections with the sleeves from BRUGG Pipes:

INDUCON (induction-welded sleeve)

INDUCON (cross-linked shrink-on sleeve)

UNLINCON(2x non-cross-linked shrink sleeve)

RANGECON (RMBD sleeve)

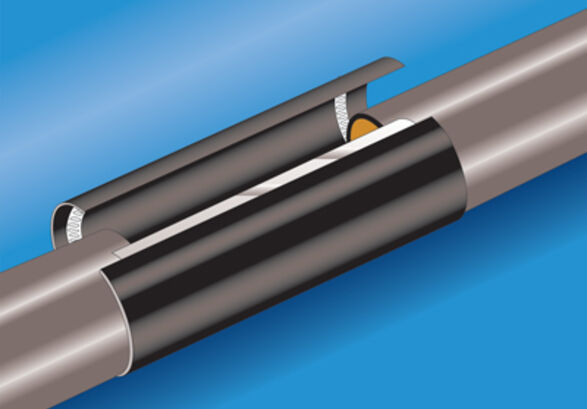

During the welding process, the casing pipe and the sleeve are heated and liquefied in a specific area. In this melted area, the materials fuse together in such a way that they cannot be broken apart again. The result is a durable, sealed weld. The INDUCON fusion coupler is the reliable solution that boasts exceptional strength and reliability. It is therefore also suitable for difficult ground conditions, as well as groundwater and pressing water.

For more information and documentation, please visit the specific INDUCON website.

Fully prefabricated HDPE plate that can be installed immediately before welding. The connection boasts consistent quality, even under difficult or restricted installation conditions. HDPE plate with heating conductor and temperature sensor on the inside.

The EWELCON electrofusion coupler creates a homogeneous connection between the casing pipe and sleeve plate so that even greater loads (e.g. the impact of temperature on the casing pipe) can be absorbed. A pipe is only as reliable and durable as its connecting components, which is why the sleeves play a key role in the design as a whole.

• Complies with specified reproducible welding parameters

• Protects against thermal damage

• Temperature-dependent power control for the CAW welding transformer

The integrated thermal element transmits the temperature data for the PE melt to the welding transformer, which is controlled by a micro-processor. This ensures precision welding.

• Protects against contamination from the building site

• Copes with diameter tolerances and the oval shape of casing pipes

• Can also be used on existing pipes (e.g. renovations)

The EWELCON electrofusion coupler is wrapped around the pipe ends, compensating for the production tolerances of the casing pipes.

• Fully automatic welding process

• Continuous process monitoring

• Welding parameters achieved are checked and documented

The welding transformer (CAW = computer-aided welding) controls the required power and determines the duration of the welding process automatically.