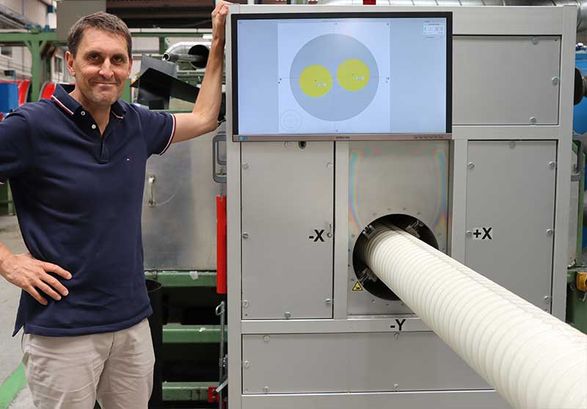

Innovative leap in quality assurance: BRUGG Pipes and the Fraunhofer Institute ITWM jointly develop a new measuring method for flexible, insulated pipe systems - based on terahertz radiation.

In order to be able to react flexibly to changing legal requirements, BRUGG Pipes has joined forces with the Fraunhofer Institute ITWM (Institute for Industrial Mathematics) to develop a globally innovative testing technology based on terahertz radiation. The background: An adaptation of the pipe structure in accordance with the EU Drinking Water Directive 2020/2184 made the X-ray testing method previously used technically impossible. The new solution enables high-precision quality control - and is a world first in the field of insulated pipe systems.

Legal requirements as a driver for technological development

The EU Drinking Water Directive 2020/2184 and the adapted German Drinking Water Ordinance stipulate an oxygen diffusion-tight aluminium layer in the inner pipe of drinking water pipes. However, this metal layer prevents the penetration of X-rays - rendering the established test procedure at BRUGG Pipes unusable.

"Our pipe systems were previously inspected inline using X-rays. With the new aluminium layer, this method could no longer be used - so we had to find an alternative solution," says Dr Jürgen Kress, Global Head of Product Development at BRUGG Pipes.

Terahertz replaces X-rays - precise, safe, future-proof

In close cooperation with the radiation experts at the Fraunhofer Institute ITWM, a technology known from the automotive industry and aviation security, among others, was adapted: terahertz radiation. It is non-ionising, harmless to health - and ideally suited for non-contact, non-destructive material testing.

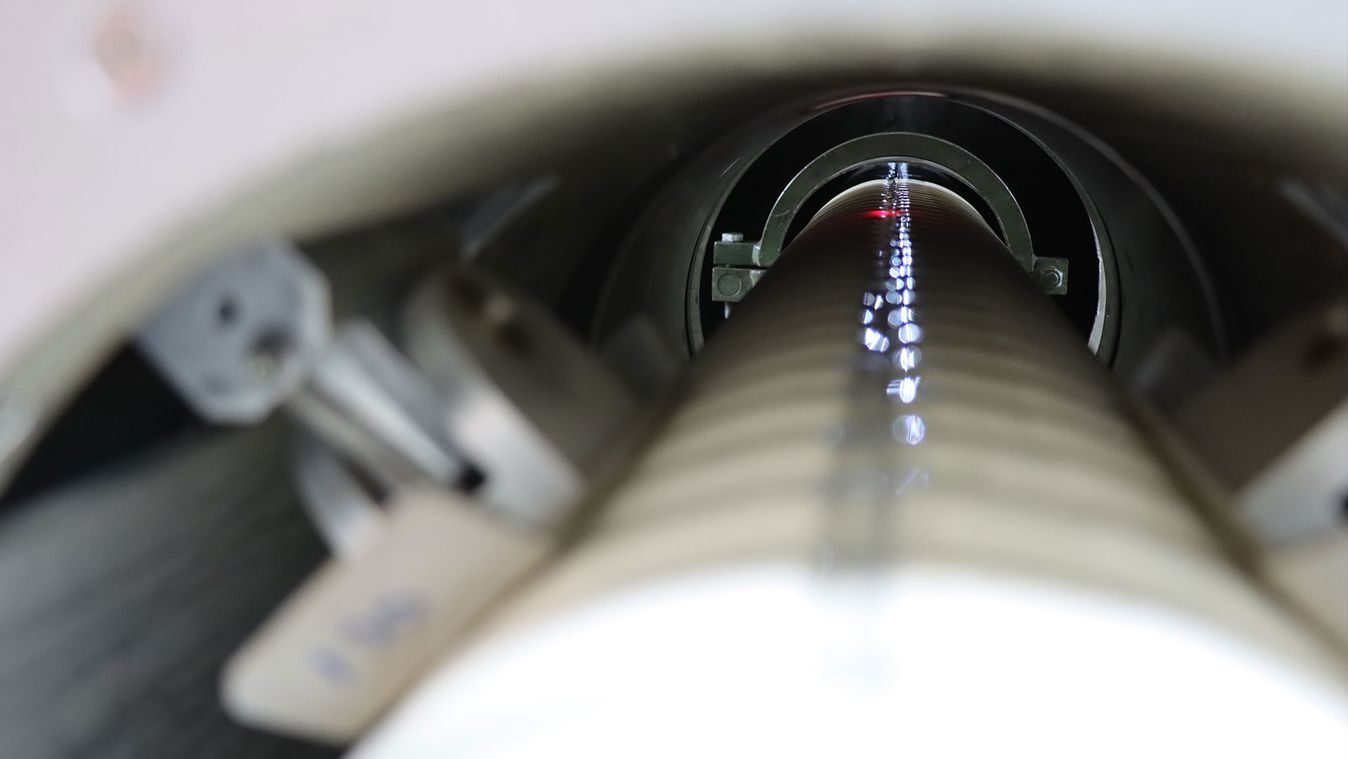

The newly developed measuring device consists of a rotating sensor that scans the pipe 50 times per second. It generates high-resolution real-time data on the centricity of the inner pipe and the even distribution of the insulating material - even in complex multi-conductor systems.